FoxCloud

FoxCloud connects seamlessly with Foxtheon’s EnergyPack and HybridPack, making it the ultimate tool for smarter energy management.

Your Energy Management Partner

Foxtheon’s FoxCloud offers advanced energy data management solutions that improve energy efficiency, reduce operational costs, and minimize environmental impact. With real-time, remote energy management, our solutions are tailored for industries, commercial offices, and public services, ensuring customizable, smarter, and more sustainable energy use for a cleaner future.

Precise Energy Consumption Monitoringn

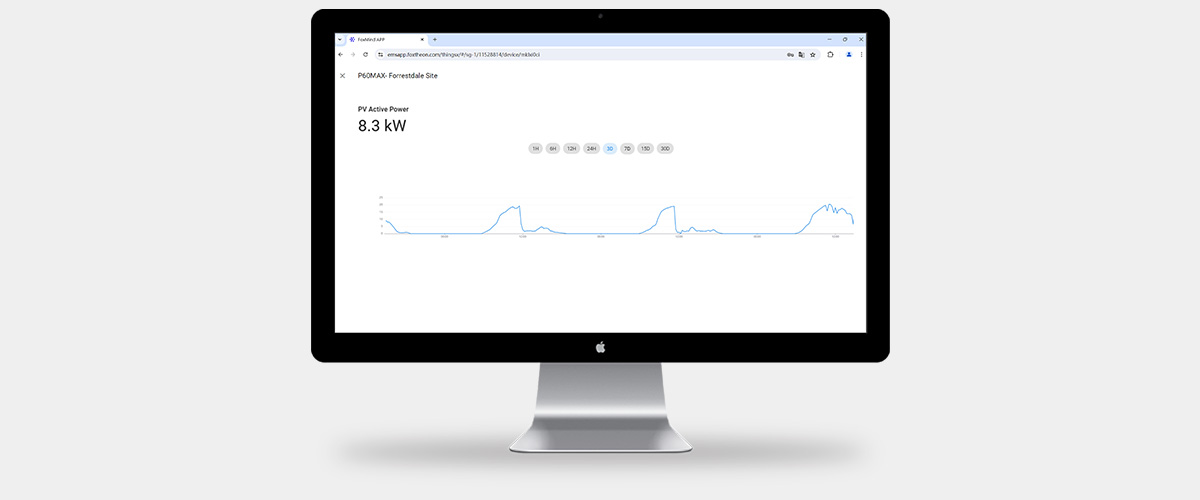

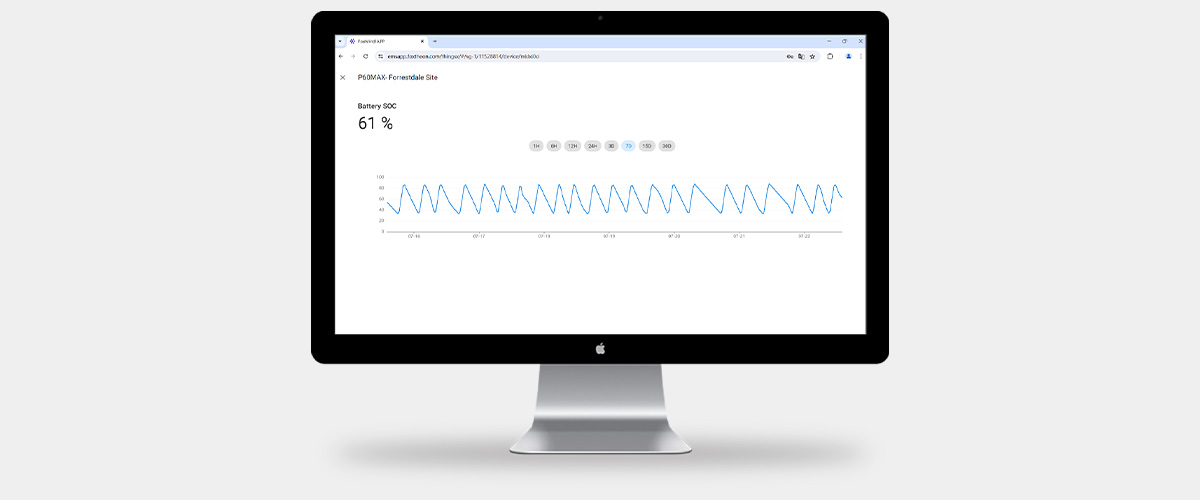

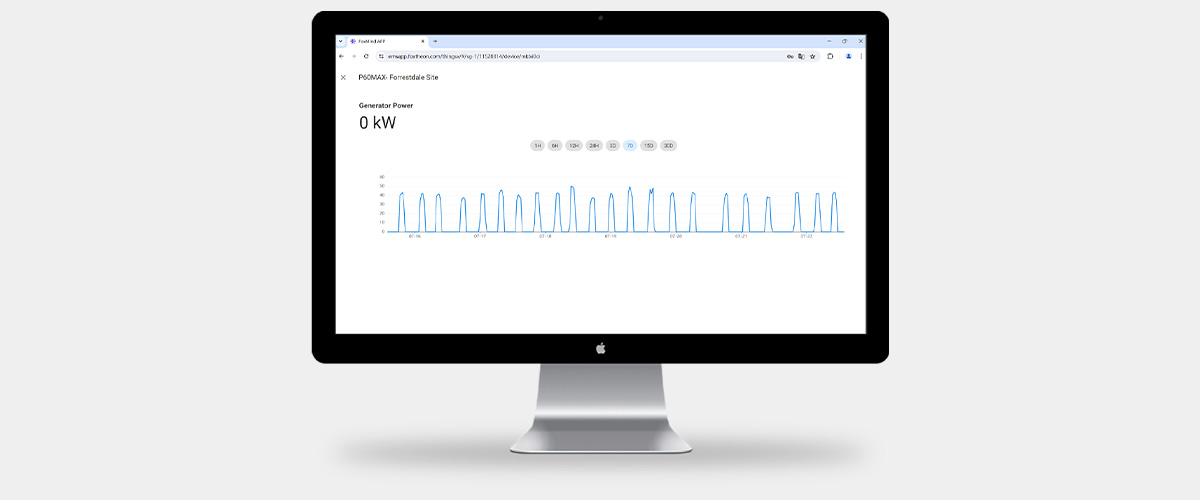

FoxCloud offers precise insights into the energy consumption of each device and area with real-time data. We provide detailed energy usage analytics to help you understand consumption patterns and trends, enabling optimized energy management strategies.

- pvFoxCloud enables real-time tracking of Photovoltaic (PV) system performance, optimizing solar energy generation and reducing costs. Harness clean, renewable energy efficiently with intelligent monitoring and management.

- BESSMonitor your Battery Energy Storage System (BESS) in real-time to manage energy storage, enhance efficiency, and extend battery life, ensuring sustainable power use and lower operational costs.

- GeneratorCustomer First, Pursuit of Excellence, Achieve Partners

Optimized Energy Scheduling

Powered by real-time data, FoxCloud supports both automated energy scheduling and manual interventions. This allows for efficient allocation of energy resources, whether optimizing equipment runtimes or adjusting energy usage during peak periods, providing flexibility and effectiveness.

Remote Device Control

FoxCloud’s cloud platform enables real-time monitoring and operational control over remote devices. This capability significantly reduces on-site operational costs while enhancing operational flexibility and response times, ensuring devices operate at peak efficiency.

Real-time Fault Detection

Using real-time data analysis, Foxtheon FoxCloud quickly identifies operational anomalies and issues proactive alerts. This approach helps prevent equipment failures, reduces downtime and maintenance costs, and ensures continuous production and service.