Background

A manufacturing enterprise in China required a reliable and sustainable power solution for its off-grid site office and production facility. The office, housing 50 employees, and the factory, which operates 5 cranes, 20 air conditioners, various testing equipment, and daily office appliances, experienced significant power demand fluctuations.

- Workdays (8:00 AM – 6:00 PM): Continuous load of 25-30kW.

- Off-hours (6:00 PM – 8:00 AM): Load dropped to 1-3kW.

Previously, the client relied solely on a rented 150kVA diesel generator running 24/7, which led to:

- Unnecessary fuel consumption during low-load periods.

- Noise pollution.

- High carbon emissions.

Project Overview

- Owner: Manufacturing Enterprise

- Location: China

- Project Type: Off-grid Site Office

- Installed Equipment: EnergyPack M100*1 + SolarPads SP5000*6

- Delivery Date: June 2024

- Key Loads: 5 Cranes, 20 Air Conditioners, Testing Equipment, Office Appliances

Objective

The project aimed to:

- Ensure reliable power supply around the clock.

- Reduce diesel consumption and associated costs.

- Minimize noise pollution.

- Lower carbon emissions to support environmental sustainability.

Site Setup

Foxtheon engineers collaborated with the client to assess the power needs and implement a microgrid solution. This involved installing an EnergyPack M100 storage system and SolarPads SP5000 units to reduce dependency on the diesel generator.

The setup allowed the client to switch from a 150kVA diesel generator to a smaller, more efficient 80kVA unit that would primarily charge the battery when necessary.

EnergyPack Storage System(M100):Installed to optimize power distribution. This system ensured that the diesel generator operated only during peak power demand or when the battery required recharging, significantly reducing fuel consumption and operational hours.

SolarPads (SP5000): Six 5kWp solar panels were installed to harness renewable energy, decreasing the reliance on diesel generators and promoting the use of clean energy.

Diesel Generator: The 80kVA diesel generator worked in tandem with the EnergyPack system, running only when needed, further optimizing fuel efficiency.

Results

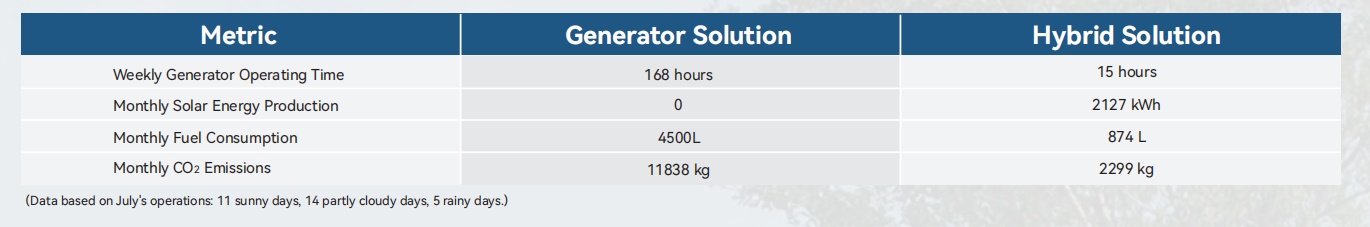

The integration of the EnergyPack M100 and SolarPads resulted in substantial improvements in efficiency, cost savings, and environmental impact.

- Fuel Savings: Monthly fuel consumption dropped by 80.5%, significantly reducing operational costs and dependence on diesel fuel.

- Reduced Generator Operating Time: Diesel generator usage decreased by 90%, saving approximately 7,848 operational hours annually.

- Lower Maintenance Costs: Reduced operational hours led to an 80% decrease in generator maintenance costs.

- Carbon Emissions Reduction: Monthly CO₂ emissions were reduced by 80%, equivalent to a reduction of 10,762kg of CO₂ per month.

Customer Voice:

“The microgrid solution turned out to be simpler than we initially thought. After the initial setup, it has operated completely autonomously without the need for manual supervision. The savings in fuel and operational costs have exceeded our expectations.We can truly feel the impact that technological advancements have had on both our work and daily life.“