The global mining industry faces a unique and pressing energy challenge. Operations are often located in remote, off-grid areas, reliant on expensive and polluting diesel fuel. Even grid-connected mines grapple with volatile energy prices and stringent environmental targets.

In this high-stakes environment, a transformative solution is gaining rapid traction: Battery Energy Storage Systems, or BESS for mining.

This technology is far more than simple backup power. It represents a fundamental shift in how mines generate, manage, and consume energy. By integrating BESS for mining operations, companies are unlocking unprecedented levels of efficiency, cost savings, and sustainability, paving the way for the intelligent, resilient mine of the future.

Why Mining Operations Need a New Energy Blueprint

Mining is energy-intensive. From massive haul trucks and grinding mills to complex processing plants, the demand for reliable, high-quality power is non-negotiable. Traditional diesel generators, while reliable, come with crippling downsides.

Fuel logistics to remote sites are costly and complex. Emissions are high, conflicting with global ESG (Environmental, Social, and Governance) goals. Furthermore, the intermittent nature of renewable energy sources like solar and wind has historically made them difficult to rely on for 24/7 operations.

This is where mining BESS becomes the critical enabler. It acts as the intelligent buffer and controller, turning variable renewable power into a firm, dependable energy source.

Core Advantages: How BESS Transforms Mining Economics

1. Dramatic Reduction in Fuel Consumption and Costs

For off-grid or hybrid mines, diesel is often the largest operational expense. A BESS for mining installation, paired with solar PV, creates a hybrid microgrid. The diesel generators can be switched off or run at their optimal, fuel-efficient load to charge the batteries. The BESS then supplies power during peak periods or at night, slashing diesel use by 30-50% or more. The result is a direct and massive cut in fuel costs and logistics.

2. Unlocking the Full Potential of Renewable Energy

Solar resources are abundant at many mine sites, but their output doesn’t always match energy demand. BESS for mining solves this by storing excess solar energy generated during the day for use at night or during cloudy periods. This turns solar from a supplemental curiosity into a primary, baseload power source, drastically reducing the mine’s carbon footprint and fossil fuel dependency.

3. Enhancing Power Quality and Protecting Critical Equipment

Mines use large, sensitive equipment that can be damaged by power fluctuations. BESS systems provide instantaneous voltage and frequency support. They stabilize the electrical network, prevent disruptions from load changes (like a large crusher starting up), and ensure the consistent power quality needed to protect multi-million dollar assets and avoid unplanned downtime.

A Practical Example: Smoothing the Load for a Grinding Mill

Consider a large semi-autogenous grinding (SAG) mill. Its operation creates huge, cyclical power demands that strain generators and cause inefficiencies. A strategically sized BESS for mining can “smooth” this load. It discharges during the mill’s peak power draw and recharges during its low-demand cycles. This flattens the load curve, reduces stress on primary power sources, and improves overall fuel efficiency.

Strategic and Operational Benefits Beyond Cost

4. Ensuring Uninterrupted Operations and Deferring Grid Upgrades

For grid-connected mines, power outages are catastrophic. A BESS provides seamless backup power to maintain safety and critical systems. Additionally, as mines expand, power demand can outstrip local grid capacity. BESS for mining can provide “non-wires alternatives,” discharging during peak demand to defer or eliminate the need for expensive grid infrastructure upgrades.

5. Meeting ESG Mandates and Social License to Operate

The pressure to decarbonize is intense. Investors, governments, and local communities demand cleaner operations. Integrating BESS with renewables is one of the most effective steps a mine can take to reduce Scope 1 and 2 emissions. This strengthens its social license to operate, meets compliance regulations, and aligns with the investment criteria of ESG-focused funds.

6. Improving Energy Security and Independence

Reliance on a single fuel source or a weak grid is a strategic risk. BESS for mining diversifies the energy mix. By creating a robust, renewable-heavy microgrid, mines gain energy independence and insulation from fuel price spikes or supply chain disruptions. This resilience is invaluable for long-term project planning.

Implementing BESS in a Mining Environment: Key Considerations

Choosing the Right Technology and Configuration

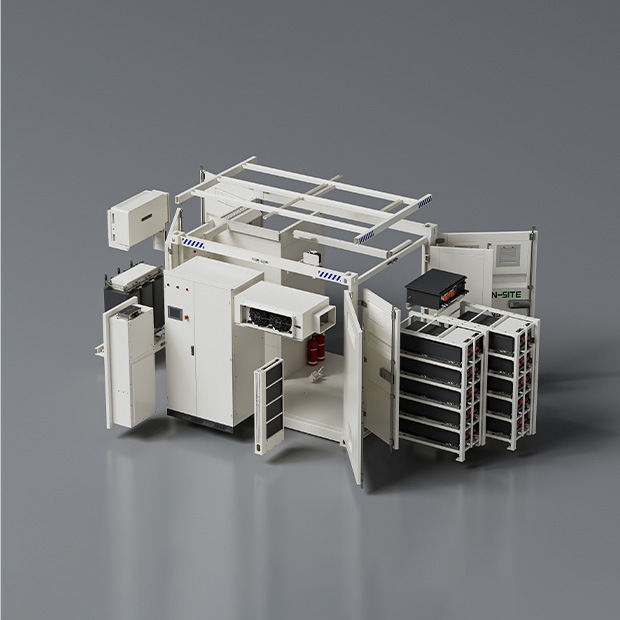

Not all batteries are suited for the harsh, remote conditions of a mine. Lithium-ion phosphate (LFP) batteries are often preferred for their safety, longer lifespan, and tolerance to wider temperature ranges. Systems must be containerized for mobility and ruggedized to withstand dust, vibration, and extreme climates.

Integration is Everything

The true value of BESS for mining is realized through sophisticated integration and control. An advanced Energy Management System (EMS) is the brain. It constantly analyzes energy demand, renewable generation, and fuel costs to optimize when to charge, discharge, or run generators. Partnering with a provider experienced in industrial microgrids is crucial. Companies like Foxtheon specialize in these integrated, smart energy solutions, ensuring the BESS works in perfect harmony with existing mine infrastructure.

The Future is an Intelligent, Integrated Mine Site

The evolution of BESS for mining is moving towards fully digitalized, autonomous energy systems. We are seeing the rise of the “smart mine,” where BESS, renewables, and even fleet electrification are managed by AI-driven platforms. These systems predict energy patterns, automate trading with the grid, and continuously optimize for the lowest cost and emissions.

This level of integration promises to make mines not just more profitable, but true leaders in sustainable resource extraction.

Frequently Asked Questions (FAQ)

Q1: Is BESS technology reliable enough for the critical, 24/7 nature of mining?

A1: Absolutely. Modern BESS for mining is built with industrial-grade, proven battery technology and robust thermal management. When integrated correctly with backup generators or a hybrid setup, it enhances overall site reliability by providing instantaneous power support and stabilizing the grid, often exceeding the reliability of a diesel-only system.

Q2: What is the typical payback period for a BESS investment in mining?

A2: Payback periods vary based on local fuel costs, renewable resource quality, and energy consumption patterns. In high-cost, off-grid diesel environments, projects often see a return on investment within 3-5 years. The savings from reduced fuel consumption, lower maintenance on generators, and avoided grid charges rapidly offset the capital expenditure.

Q3: Can BESS be used to power electrified mining equipment, like haul trucks?

A3: While direct, mobile propulsion for ultra-large haul trucks is still emerging, BESS plays a vital supporting role. It can provide fast-charging infrastructure for a fleet of smaller electric vehicles and support the increased grid demand from stationary charging stations for larger trucks, ensuring the overall mine microgrid remains stable.

Q4: How do you handle the end-of-life for batteries in such a remote location?

A4: Responsible lifecycle management is a priority. Many batteries retain significant capacity after their first life in mining and can be repurposed for less demanding commercial storage. Providers with strong ESG principles, including Foxtheon, design systems with recyclability in mind and partner with certified recycling chains to ensure materials are recovered responsibly at the final end-of-life stage.

Q5: We have an existing diesel power plant. Can BESS be added to it?

A5: Yes, this is a common and highly effective approach. Retrofitting a BESS to an existing diesel plant is a standard pathway to create a hybrid system. The BESS integrates with the plant’s controls, allowing generators to run at optimal load, reducing wear and tear, and saving fuel immediately. This is a practical first step toward decarbonization.

The business case for BESS for mining is now undeniable. It has evolved from a niche concept to a core strategic investment for any mining operation serious about controlling costs, ensuring reliability, and securing its future in a low-carbon world.

By embracing this technology, the mining industry can power its essential work in a smarter, cleaner, and more profitable way. The journey toward the fully sustainable mine is complex, but it is powered by intelligent energy solutions. Implementing a robust BESS for mining strategy, supported by experienced partners, is the critical next step on that path.

As the industry continues to innovate, collaboration with technology leaders who understand the unique demands of mining—like the team at Foxtheon—will be key to unlocking the full potential of this energy revolution.